Machine Tending Robot Cell Design

Machine Tending Robot Cell Design

Process Robotics offers comprehensive machine tending cell design solutions aimed at streamlining manufacturing processes through advanced automation. These solutions are carefully engineered to increase efficiency, reduce downtime, and improve overall productivity. Each design is tailored to meet the specific requirements of the production line, ensuring seamless integration and performance within your facility's existing workflow.

Learn More

Custom Machine Tending Cell Design

Designing an efficient machine tending cell requires attention to several key factors, including optimal material flow and secure workholding. Our machine tending cell design includes:

- Material Infeed & Outfeed Design: Ensures smooth material handling, minimizing interruptions and facilitating continuous production.

- Custom Automated Workholding: The integration of pneumatic workholding or hydraulic workholding ensures that workpieces are securely held during the manufacturing process, enhancing stability and precision.

- Machine Auto Door Solutions: Automating machine access with automatic machine door openers helps improve workflow efficiency and operator safety.

These carefully crafted solutions support seamless, efficient operation and provide flexibility to adapt to evolving production needs.

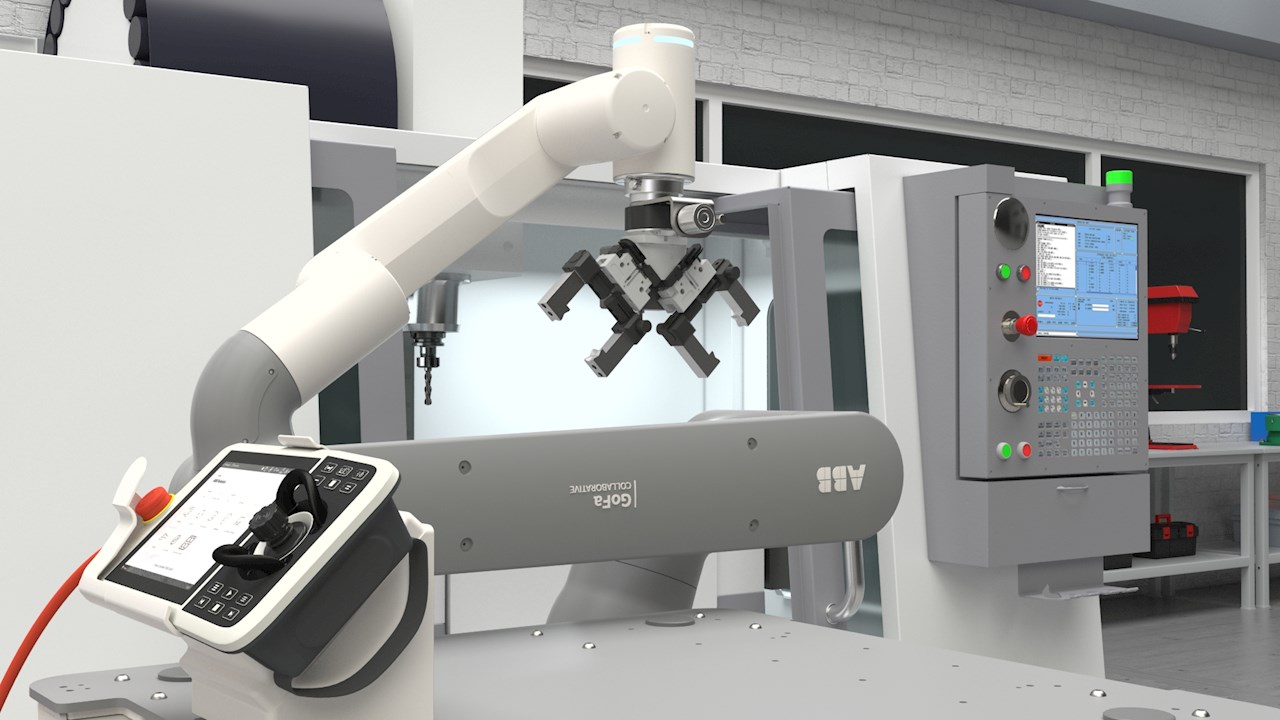

Custom End of Arm Tooling (EOAT) for Precision Handling

The right end of arm tooling (EOAT) ensures that each piece is handled with precision and care. Whether through custom EOAT solutions or standard EOAT solutions, our offerings include:

- Custom EOAT: Tailored to meet specific production requirements, designed for maximum precision and efficiency.

- Custom Gripper Fingers: Precision-engineered gripper fingers are designed to handle delicate or complex parts with accuracy.

- Standard EOAT Solutions: A range of readily available EOAT options for quicker deployment across various applications.

By integrating the right EOAT design, manufacturers can optimize machine tending operations while ensuring minimal handling errors and increased productivity.

Your partner for Machine Tending cobot solutions.

Process Robotics™ machine tending solutions help you automate repetitive, time-consuming tasks, freeing up your workforce to focus on higher-value activities. With our expertise in the latest technologies and industry best practices, we can increase productivity, reduce costs, and improve quality across your operations.

Optimized Robotic Layout and Reach Study

An effective machine tending cell begins with a carefully planned layout and a detailed robot reach study. Key elements include:

- Efficient placement of robotic arms: Maximizes reach and accessibility within the cell.

- Optimized machine integration: Minimizes downtime and streamlines operations.

- A layout designed to enhance both speed and accuracy: Ensures precision in machine tending tasks.

These design considerations ensure that the robotic cells work within their full potential, providing flexibility and improving overall performance.

Machine Monitoring and Fleet Coordination

Machine tending cells are optimized with machine monitoring and fleet monitoring capabilities, enabling manufacturers to track the real-time status of equipment across the entire production floor. Features include:

- Machine Monitoring: Provides real-time visibility into machine performance, helping identify issues before they cause downtime.

- Fleet Monitoring: Tracks multiple robots and machines across a facility, coordinating efforts for maximum efficiency and uptime.

- MTConnect Adapter: Facilitates seamless communication between machines, ensuring interoperability and smooth data exchange for more informed decision-making.

These systems are powered by IIOT and Industry 4.0 technologies, ensuring that your operation is both connected and future-ready, with the ability to integrate new technologies as they emerge.

Empowering Smart Manufacturing with Machine Tending Automation

The machine tending cell design offered by Process Robotics is more than just a robotic system. It is an integrated solution that supports smart manufacturing by combining automated machine management, factory automation, and data-driven insights. With real-time machine monitoring, MTConnect compatibility, and seamless interoperability, manufacturers can confidently improve efficiency, reduce waste, and boost overall productivity.

Contact Us

To explore how custom machine tending cell design can enhance your production process, get in touch with Process Robotics today. Our team of experts is available to discuss your specific needs and develop a tailored solution that drives efficiency and performance.

- Phone: 888-99-COBOT

- Email: info@processrobotics.com

- Location: Portland, OR

Contact Process Robotics today and discover the potential of customized machine tending automation solutions.

'

'